Martechnic specialises in oil quality management and provides engineers and users with on-site analysis equipment for condition monitoring of lubricant and hydraulic oil, such as marine distillate and marine residual fuels.

Crucial oil parameters can get measured either regularly with the help of portable oil test devices and test kits or on a continuous basis employing permanently installed advanced sensor technology.

The key advantages Martechnic offers its customers include quick and precise information on any occurring changes or abnormal processes in the engine oil condition, effective decision-making on corresponding actions, as well as proper oil system predictive maintenance and the possibility to ensure optimal performance of critical machinery.

Fast and individual response, customer-specific applications and tailor-made solutions, efficient order processing and comprehensive logistic support relate to Martechnic’s principal business lines.

Portable oil test devices and test kits

A variety of portable test devices and test kits is developed and designed by Martechnic to check directly on-site and beyond laboratory practice such essential parameters of lube and hydraulic oil as water-in-oil, alkalinity reserve (BN, TBN), viscosity, density and contamination with insoluble or metal particles.

Regular verification on the basis of trend analysis enables early detection of irregularities in the oil condition. Quick and accurate test results with possibility of immediate assessment help to effectively implement condition-based maintenance programs.

Test cabinets for on-board analysis of fuel and oils

To support vessels with their own on-board oil analysis laboratory, Martechnic supplies a Fuel and Lube Oil Test Cabinet, which contains a selection of portable test devices for easy and fast condition analysis of all principal parameters of fuel, lube and hydraulic oil.

Owing to instant availability of test results, the quality of the delivered bunker fuel and the condition of lubricants and hydraulic oil in use can be regularly monitored and promptly evaluated. This helps to ensure the smooth operation of constituent engine parts as well as provides immediate decisions regarding maintenance, including the possibility of prolonging maintenance intervals.

Sampling equipment for representative oil samples

Accurate results of oil condition analysis imply the availability of representative oil samples. Martechnic offers a full range of sample bottles, cubitainers, drip samplers and sampling kits elaborated for safe collection, retention and transport of representative samples of fuel, lube and hydraulic oil. Sampling bottles differ in size, shape and material depending on the oil to be tested.

All sampling equipment for fuel oil samples is in compliance with MARPOL Annex VI requirements. For collection of primary bunker fuel samples during bunkering, Martechnic supplies manual-valve drip samplers equipped with cubitainers which are attached and reliably protected from tampering and contamination through the special sealing system. Safe storage of retained fuel oil samples is achieved by means of a combination of sampling bottle, proper label made of tear resistant and tamper proof material and individually numbered sealing.

Martechnic’s Sampling Kit is a vacuum hand pump with a flexible tube coupled with an adaptor at a sample bottle. The kit is suitable for sampling collection from different parts of the oil tank, and can be applied to determine free water in the oil tank and possible ongoing friction processes.

Advanced sensor technology for continuous oil condition assessment

Undetected changes in condition of lubricating and hydraulic oil can cause malfunctions in machinery systems. Installation of on-line or in-line sensors provides continuous 24/7 monitoring of essential oil parameters and enables real-time detection and tracking of any occurring changes.

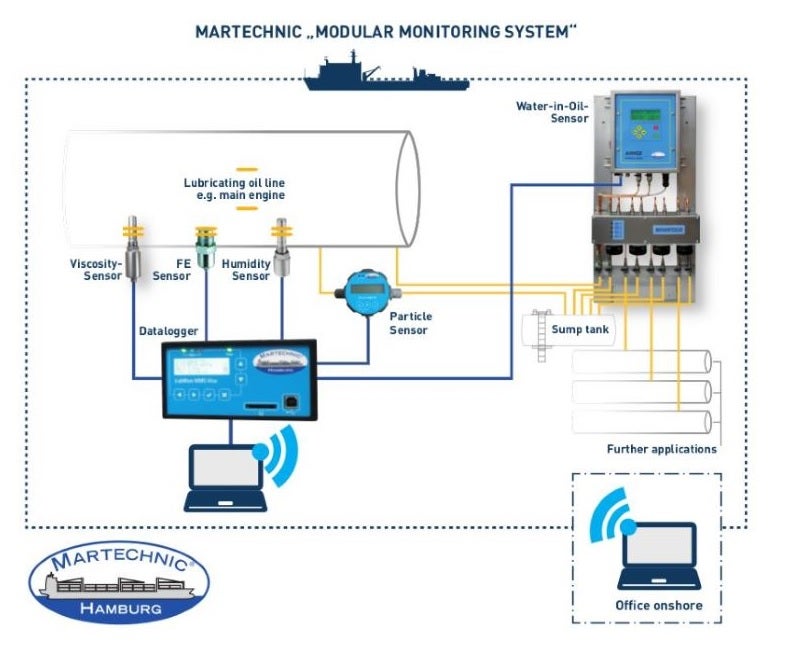

Martechnic has developed a Modular Monitoring System, which encompasses various sensors (viscosity, particle, humidity, FE and water-in-oil sensors) and due to its modular design can be installed in accordance with individual customer-specific application needs.

On-board a vessel, the sensors can be installed for controlling the oil condition in generators, main engines and hydraulic systems. The possibility to set an individual alarm level for each oil parameter under surveillance enables an immediate warning as soon as the critical range is reached, allowing immediate corresponding actions and determination of the root cause of the problem.

All the sensors can be connected with the all-purpose display and data processing unit Datalogger for easy recording, transmitting, displaying, reading and storing of the data.

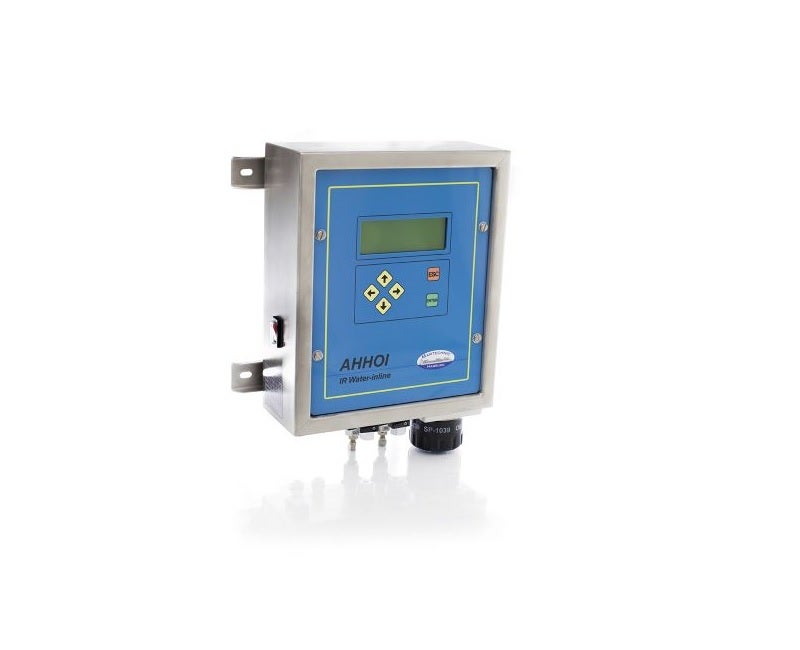

For continuous monitoring of absolute content of water in lubricants Martechnic has developed the AHHOI – Infrared Water-in Oil Sensor. Installed in the bypass, the sensor measures water molecules present in oil up to 10,000ppm / 1.0% vol. irrespective of the state of water: saturated, emulsified or free. The sensor can be used in a combination with a manifold for monitoring the condition of up to four engines (for example the main engine, hydraulic systems or stern tube seals).

Ultrasonic cleaning equipment

Martechnic offers ultrasonic cleaning tanks, generators, submersible transducers and cleaning liquid for safe, thorough and efficient cleaning of different engine parts (for example, cylinder covers, coolers, valves, lube and fuel oil filters) and in particular difficult-to-reach areas. Alongside standard sizes, customized options can be ordered.